| allitwares > Contenido del producto Noticias > Extruder Combination provides More Energy-Efficient Without Gears |

|

|

| Extruder Combination provides More Energy-Efficient Without Gears |

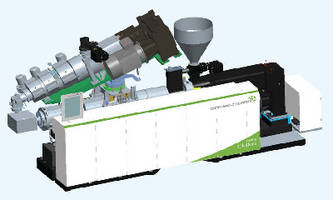

battenfeld-cincinnati responds to current industry trends towards an increasing use of recycled materials in window main profile production by presenting a compact extruder combination. At the K, the Construction Division will show-case the conEX 63 P conical extruder mounted in piggyback configuration on a twinEX 78-34P. In addition to saving space, this combination offers a cost advantage and the ad-ditional benefit of customer-friendliness thanks to easy op-eration. The new piggyback solution also meets all re-quirements of high energy efficiency, since both extruder models are equipped with proven energy-saving features as standard.

For economic as well as ecological reasons, more and more recy-cled materials are incorporated in the production of window main profiles today. In some cases, these materials make up more than 40% of the total weight and are used wherever they are not visi-ble. All visible surfaces are still made of virgin material. battenfeld-cincinnati has now designed the twinEX/conEX piggyback extruder combination precisely for such applications with a high proportion of regrind. The two counter-rotating twin-screw extruders combined achieve an output of about 500 kg/h, with the parallel twinEX 78 being able to plasticize up to 290 kg/h, and the conical conEX 63 handling up to 220 kg/h.

Thanks to the coextruder’s flexible frame design, this machine combination offers maximum flexibility in die connection facilities, so that die changes are made easy. The extruders have a common control cabinet, which saves both costs and space and makes the equipment easy to operate as well. Both extruders can be operated via one common control panel, and the die comes with a central plug, which also contributes to the equipment’s special user-friendliness. The die can be connected quickly and easily, and op-erating errors such as incorrect wiring are totally excluded.

The piggyback solution leaves nothing to be desired in terms of high energy efficiency either. Like all extruders from battenfeld-cincinnati, these also operate with maintenance-free AC motors for maximum efficiency across the entire process window. The self-optimizing, maintenance-free Intracool screw core tempering sys-tem is also extremely energy-efficient. The extruders come with fully insulated barrels, which substantially reduce energy loss through heat radiation and simultaneously ensure high process stability thanks to temperature constancy. The latter is provided by additional intelligent features, such as a special air cooling system for the barrels, which prevents heat loss and simultaneously ensures even temperature distribution over the entire barrel cross-section of the processing unit. |

| Etiquetas: |

| |

| Acerca de esta empresa: |

From the merger of Battenfeld Extrusionstechnik, Cincinnati Extrusion and American Maplan, battenfeld-cincinnati, the global market leader in extrusion technology, has emerged.

The three operative divisions Construction, Infrastructure and Packaging hold leading positions in their target markets in the areas of innovative strength, product quality, problem-solving expertise and service. This makes us a partner who is appreciated by our customers, suppliers and business partners worldwide.

We are a global player. Our locations are Bad Oeynhausen and Kempen (Germany), Vienna (Austria), Shunde (China) and McPherson (USA). Our worldwide service network ensures all-time availability of all installed lines. battenfeld-cincinnati develops, designs, manufactures and distributes high-quality, innovative extruders and extrusion equipment for plastics processing. |

| Empresa: |

| Nombre de la empresa: |

battenfeld-cincinnati |

| dirección: |

Königstr. 53 |

| ciudad: |

Bad Oeynhausen |

| provincia: |

|

| ZIP: |

32547 |

| país: |

Germany |

| número de teléfono: |

+49-5731-242-0 |

| FAX: |

+49-5731-573127124 |

|

|

|

| |

| Nota: Las marcas, nombres de producto, el número de productos mencionados en este contexto, los derechos de autor pertenecen a la empresa. |

| |

|